Wai Man has a dedicated Finishing Department and provides all finishing services in-house. As always we follow sustainable trends in all production techniques including the selection of Finishing techniques listed below.

Print finishing encompasses post-printing actions, such as value-added operations after ink application. These techniques enhance the function and appearance of printed pieces, with some occurring before the press (inline) and most after (offline).

Lamination bonds a clear plastic film to printed material, providing protection against stains, smudges, moisture, and tears. Gloss and matte finishes are available, with gloss enhancing ink colors. Widely used for durable items like educational materials, flip charts, book covers, menus, maps, and consumer displays.

Choose from Scratch-Free Gloss or Matt Lamination for your printed materials. While matte finishes have a subtle look, they can reveal marks more easily. To combat this, opt for anti-scratch matte lamination or enjoy the added tactile sensation of soft touch matt lamination, which offers excellent protection.

Foil stamping uses heat and pressure to apply metallic foil designs to printed pieces, typically in gold, silver, or copper tones, with various color options. This process adds elegance and distinction, and when combined with embossing, creates striking raised metallic designs for a unique and sophisticated appearance.

UV varnishing employs an ultraviolet drying machine, offering a vivid, luxurious, and tactile finish superior to non-UV varnishes. Available in matt, satin, or gloss finishes, it provides an instant professional appearance. This quick and efficient process can cover the entire printed area or specific sections for enhanced visual appeal.

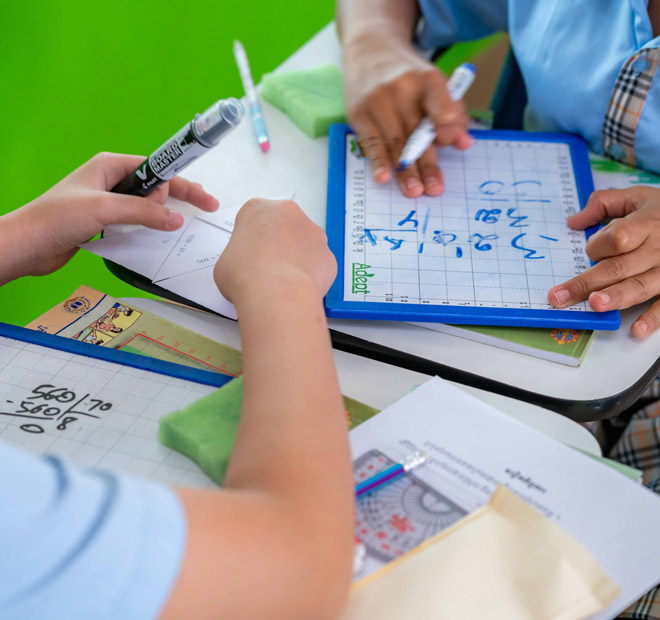

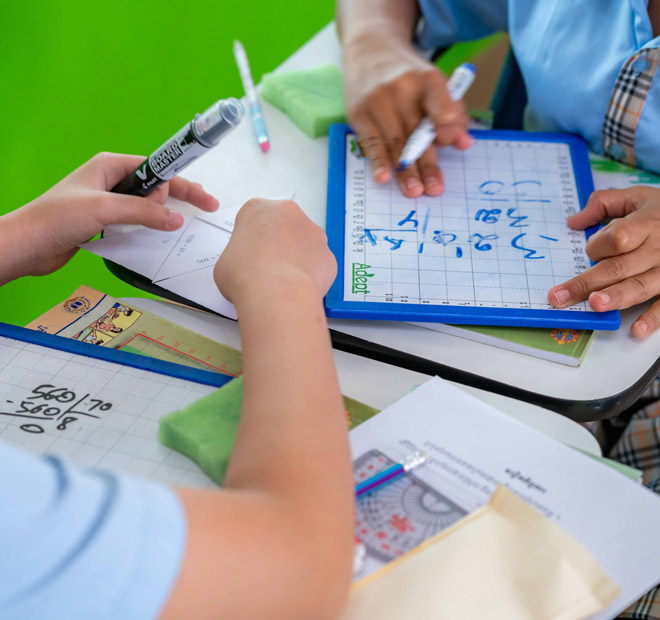

This is a new technique, only available at very select printing companies, which allows the end user to write in pen or pencil on top of the finished product. Ideal for use in educational materials.

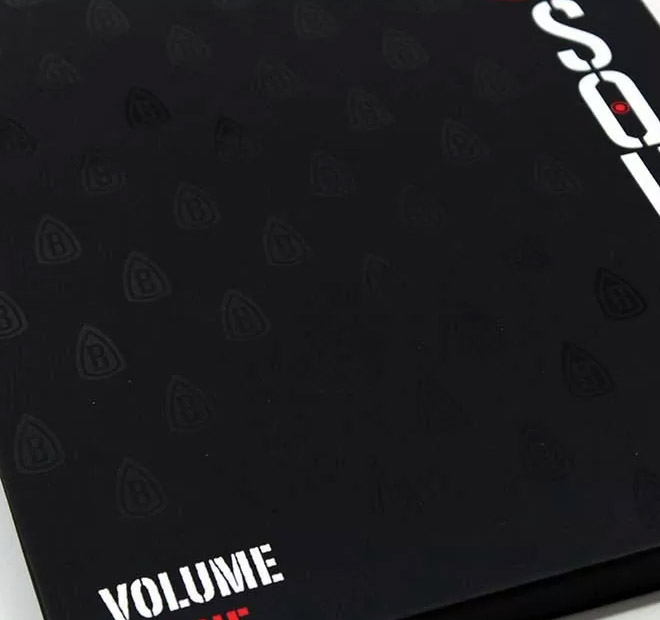

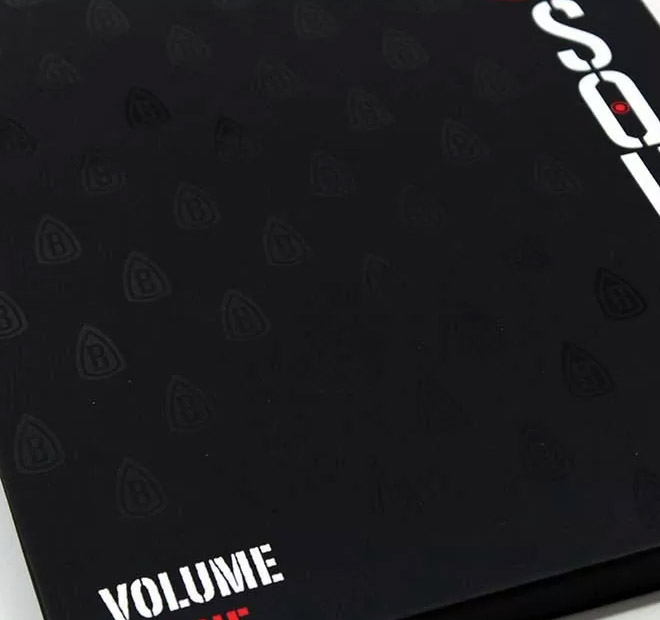

Spot UV printing is a popular coating technique, adding a glossy, raised effect to printed materials. It involves applying a clear, shiny UV varnish to specific areas for contrast. Widely used for business cards, postcards, and marketing materials, Spot UV enhances designs and exudes luxury and professionalism. It elevates a brand’s image, making it more appealing to consumers and enhancing product appearance on store shelves.

Glitter printing, a transfer printing process, uses glitter powder to add shine to fabric, making it perfect for formal party wear. The advantages of glitter print include adding sparkle, suitability for any fabric color, resistance to high temperature and pH solvents, and ideal use for fashion and party wear.

Flittering is a production process where cards are adorned with glitter to create a sparkling effect. It commonly refers to multi-colored, iridescent flakes used in the greeting card industry. Flittering is associated with thermography-based finishes that produce a shiny, eye-catching appearance.

Flock screen printing, also known as flocking, involves adding dye, adhesive, and tiny fiber particles (flock) to garments, creating a velour, fluffy, velvety texture. Flock can be made from natural or synthetic materials like cotton, rayon, nylon, or polyester. This technique enhances garments’ touch, color, and appeal, making them stand out and providing a silky, velvety finish to various materials.

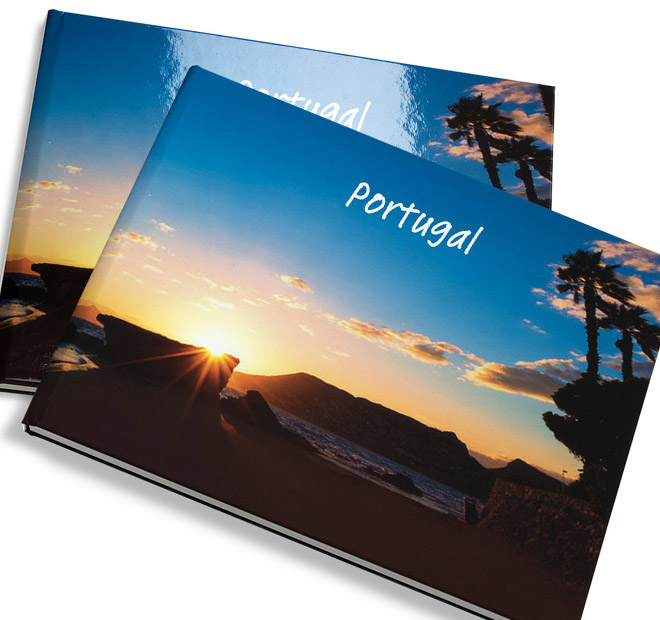

Binding is the process of gathering and fastening separate sheets or signatures, creating durable books and booklets. Methods include perfect binding, saddle-stitching, spiral/coil binding, wire-o binding, pro-click binding, hardcover binding, and insertion into ringed binders.

This process is where the paper or card is coated with a thin layer of nontoxic black ink or paint, under which lies a kaleidoscope of hidden color – scratch away at the surface to create patterns and messages in random but bright hues.

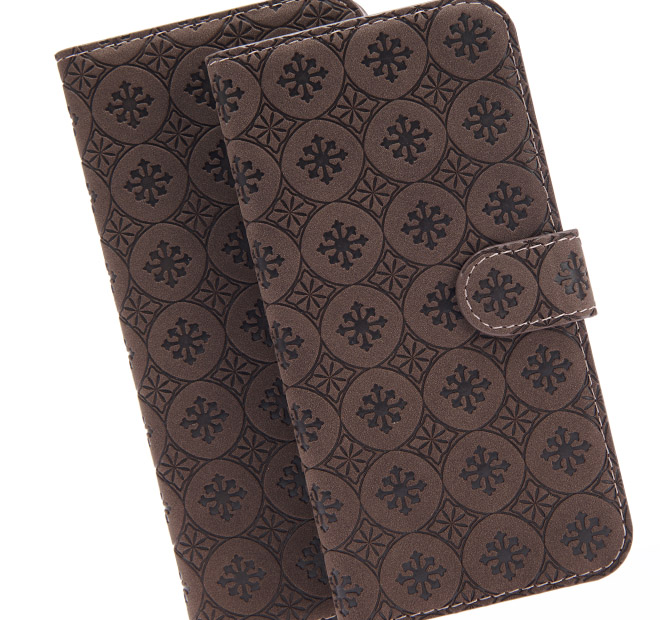

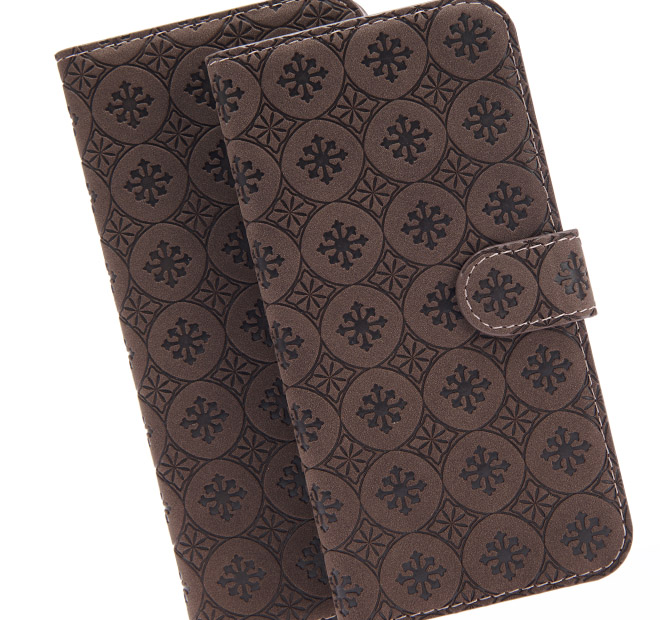

Blind embossing is the process of pressing a design or pattern into the surface of paper or cardstock without adding any ink or foil. Often used to create a subtle, elegant effect on stationery and other high-end printed materials.